Almonds are quickly changing the world. Not only has really great marketing educated consumers about the health benefits of almonds, but there are also a lot of great new products that have been derived from almonds, including almond milk, almond flour (I am now using this to make cookies), etc. In order to get these almonds into our homes, there are a multitude of steps that need to be taken to harvest and process nuts. In this post, I am highlighting the almond harvesting process at RPAC Almonds and Parreira Almond Processing in Los Banos, California. (You can click here to see the rest of the story with a tour of their almond processing facility!)

Table of Contents

Almond Harvesting Process

There are three main steps that take place during the almond harvesting process.

- Shaking

- Sweeping

- Harvesting

Almond Shaking

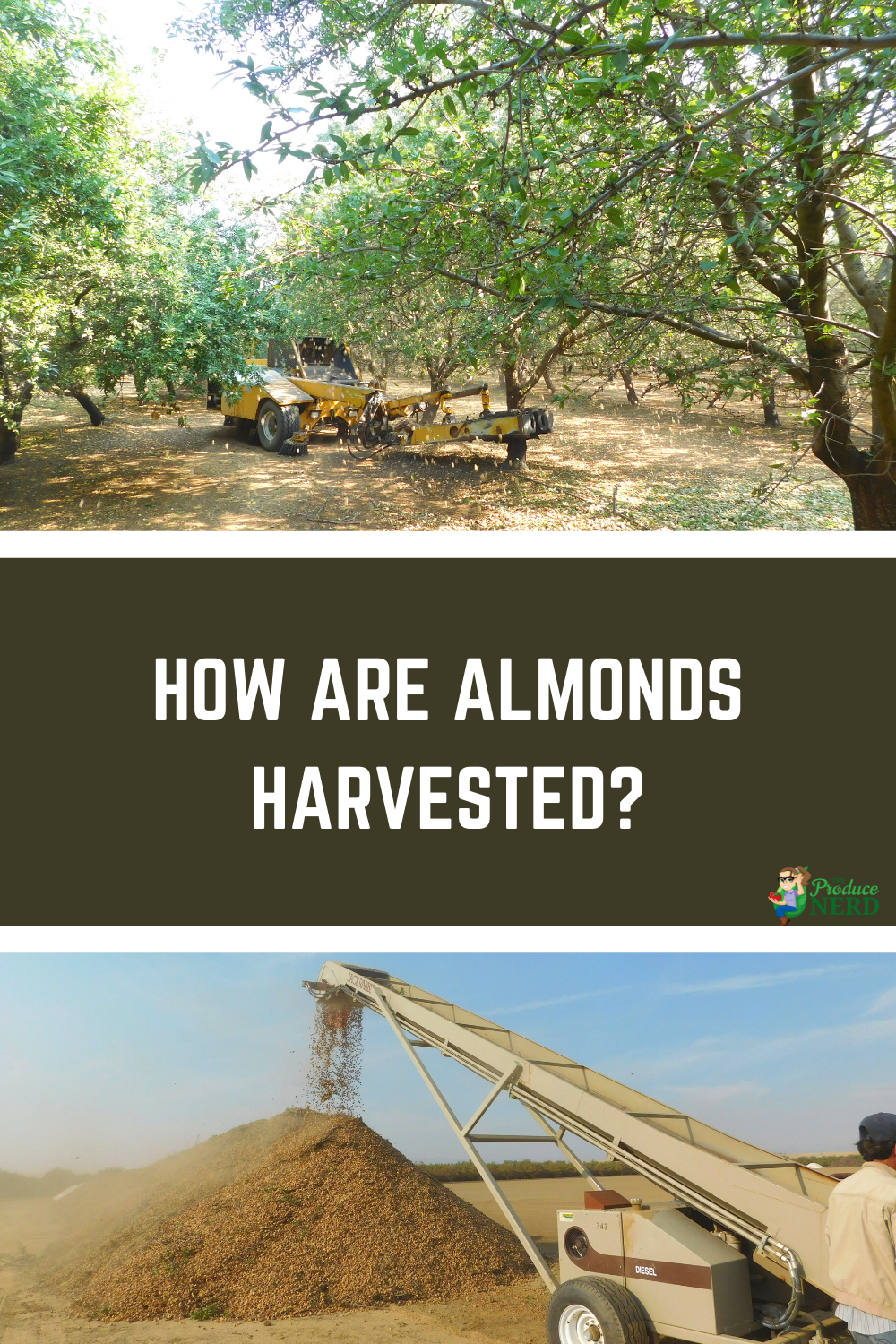

When almonds are ready to be harvested, a shaking machine enters the field. Shaking machines are used on each individual tree in order to shake the nuts off the tree. The shaking machines have guards on their grips, so that they do not cause any damage to the trees.

How to Know When Almonds are Ready for Harvest?

Once the nuts are shaken off the tree, they are left in the field for approximately 4 – 7 days to dry. The drying time is determined by the resulting moisture content of the kernel and outer hull. A sample size of the field is taken to determine an average moisture content for the field and, therefore, when to harvest.

Below is an example of what the outer hull looks like at the time of shaking.

Almond Sweeping

Once the almonds have reached the desired moisture content, sweepers go into the field to sweep the nuts into a windrow. This step is essential because the harvesting machine has a certain area in which it is able to pick up the nuts.

You can see in the picture below that there are not just nuts located in the swept windrows. There is also excess soil and field debris (e.g., twigs, leaves, etc.). This also gives you a better idea of what the outer hulls look like as harvest approaches.

Almond Harvesting

After the rows have been swept, the harvesting machine follows. The harvester moves through the field and as it collects all of the nuts that have been swept into the windrows, it also discards all of the additional soil and field debris that is picked up with the machine.

Once the trailers at the back of the harvesting machines have filled up, a self-propelled shuttle links up with it where it is located in the field and the harvested nuts are offloaded into the self-propelled shuttles.

The almonds are then stock piled in a separate location from the field. Depending on the location from the stock pile yards, these shuttles either unload the almonds into an elevator that leads to a truck trailer (if the stock pile is far from the harvested field) or into an elevator onto the stock pile (if the stock pile is close to the field that is being harvested).

Almond Stock Piles

Once the trucks or shuttles arrive at the stock pile, they unload the harvested nuts onto elevators that create stock piles. The nuts are stored here as there is an excess of harvested product during the harvesting season and all of the nuts cannot be ran through the facility on the day of harvest. These piles are created based on the grower, field, variety and date of harvest. Each individual stock pile that you see is separated and can be traced back to its harvest location and date.

Below, you can see what this process looks like when a self-propelled shuttle goes to the stock pile yard directly from the field.

Meanwhile, this is what the process looks like when a trailer brings harvested product to the stock pile yard.

Fumigating Almonds

In order to keep the nuts free from pathogens and insects, the conventionally (non-organic) grown nuts are fumigated within 2 days of being placed in the stock piles. The nuts are stored in the stock piles under plastic tarps that are held down with sand. In order to fumigate, a small hole is punctured into the plastic tarp, the fumigant is inserted, and the hole is taped back up.

There is an approximate harvest window that lasts around 60 days, and it will take around 120 days to process (hull and shell) all of the nuts that get harvested.

Almond Harvesting Video

To see further details related to the step-by-step harvesting process, check out the video below!

Are you wondering what happens after the almond harvesting process? Check out the almond processing (follow up) post!

Featured Grower Information

I would like to send a big thank you to RPAC Almonds and Parreira Almond Processing for the tour. They are almond growers and processors located in Los Banos, California.

If you enjoyed this post, you might also be interested in reading: