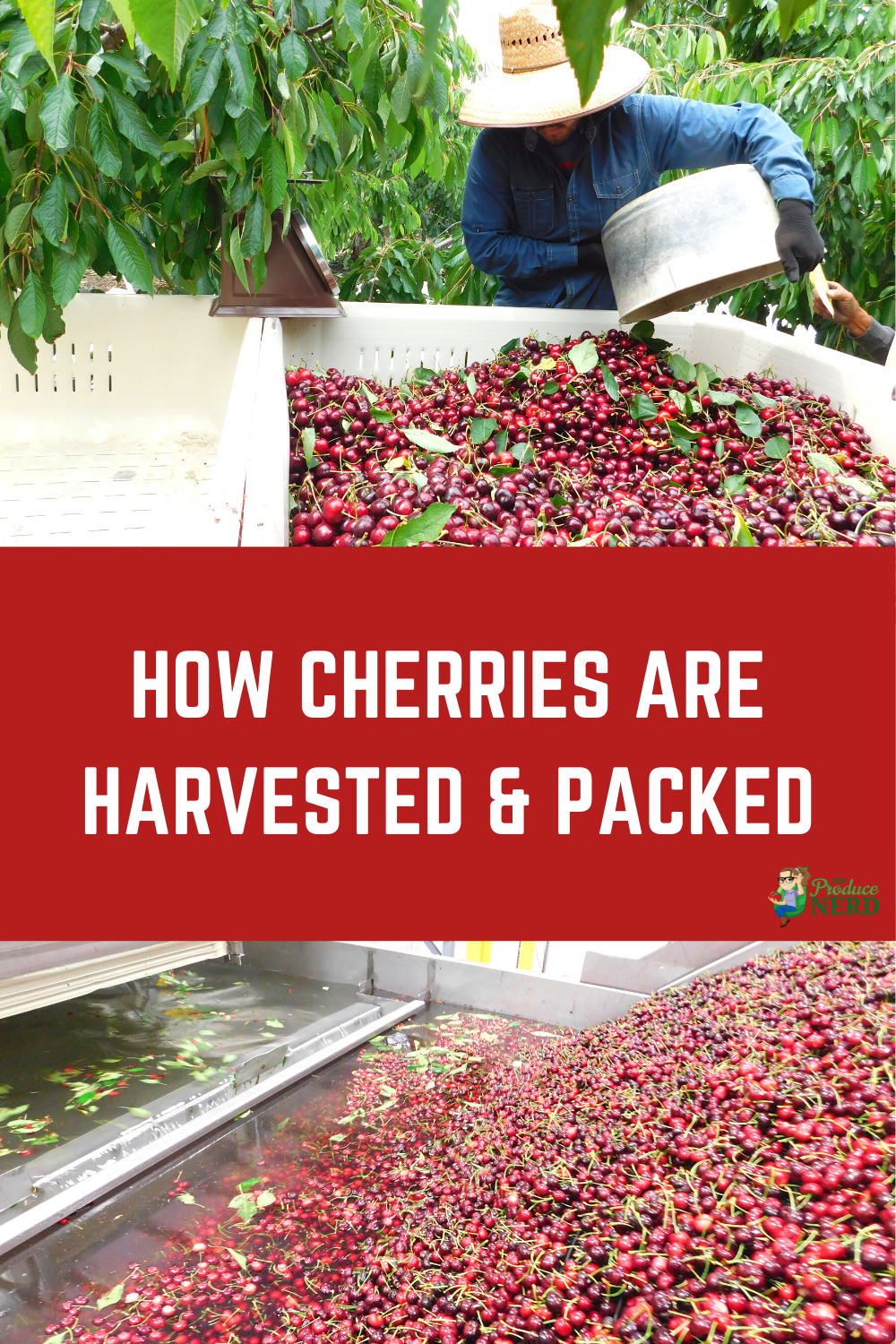

Have you ever wondered what it takes to get cherries to the grocery store during their short window each year? The cherry growing, harvesting and packing process takes a lot of work, time and attention. I recently took a trip to The Flavor Tree Company in Hanford, California to be able to demonstrate the different steps of the cherry harvest and packing process.

Table of Contents

How do Cherries Grow

Cherries grow in large clusters on trees. The amount of fruit that is set is based on the flower blossoms produced (starting in February in California), and the weather and environmental conditions that follow up until the cherries are harvested.

How are Cherries Harvested

Cherries are hand harvested into bins. It is common that workers will go through and harvest one tree for the ripe cherries (looking for soluble solids content (sugar content) and a dark skin color for the red varieties), and then will have to return a few weeks later to harvest the rest of the cherries as they have ripened further. Cherries are different from other types of stone fruit, in that they are non-climacteric, and do not continue ripening after harvest.

After the harvesting buckets have been filled, they are taken to the bin storage in the middle of the field. They are weighed and dumped gently into the bins to prevent causing any damage to the fruit.

How are Cherries Packed

After harvest, the harvested cherry bins are transported to the packinghouse. In the video below, Garrett Quade from The Flavor Tree Fruit Company narrated the walk through of their cherry packing house.

Once the cherries arrive at the packing house, these are the steps that follow:

- Arrival – Cherry bins are brought into the facility with a forklift.

- Bin Dump – The bins are lifted up into the bin dump, where the cherries are dumped into sanitized water (to decrease the impact of the drop on the fruit). When the cherries are dumped into the water, those that float are removed, and the rest continue on a conveyor belt to continue along the cherry packing line.

- Separating Cherry Clusters – When cherries grow and are harvested, they are harvested as clusters and not as individual cherries with an individual stem. As a result, there is a section of the packing line where there are cutters that are meant specifically to cut the bunches so that the cherries come out as individual cherries (not being connected to another cherry via the stem).

- Hand Sorting – The cherries are hand sorted for defects, including decay and splits. Throughout this process, the same fruit continues down the conveyor belt passing multiple sorters. There are brushes along the line to rotate the fruit so that if there was a blemish on one side of the fruit that was missed by one worker, after the fruit is rotated, another worker will catch it. There are two options for getting rid of the fruit in this case: culls (garbage or animal feed) or redistributed to a secondary market (e.g., double cherries for produce markets).

- Hydrocooling Cherries – Cherries go into the hydrocooler to remove any residual field heat, so that all cherries come out at the same temperature (~32-34°F) when they go to the cooler. This step is where the sanitizer is added to the water. (Depending on the commodity and the packinghouse, the water used in the wash step can either be recycled or used as single use.)

- Optical Sorter – The fruit goes through an optical sorter to be sorted by size and for any defects that were missed previously. This sorter designates the fruit to certain packing lines so that the fruit can be packed together with the other fruit that is the same size. (This is done to meet customer specifications and also to ensure that the packer is receiving proper compensation.)

- Packing into Bags – Once the allocated amount fills the scales, the fruit drops into the bags. The bags are then packed into boxes and once the boxes are filled, they are sent onto another conveyor belt. Within the boxes, there is an additional bag surrounding the bags of packed cherries. This bag acts as modified atmosphere packaging (MAP), and is used to extend the shelf-life of the cherries.

- Quality Control – There is a final weigh and quality step to make sure the boxes meet customer specifications. If they do not weigh enough, additional fruit will be added.

- Palletization – The boxes are then packed onto pallets and sent to the cooler to await transport.

Food Safety Considerations

For a cherry harvesting and packing operation, some of the main food safety concerns are:

- Sanitation of the harvesting buckets and bins – Cleaning and sanitizing of the buckets and bins needs to occur on a regular and frequent basis.

- Testing and changing of the wash water – The cherries are exposed to water during the packing and hydrocooling process. The water is recycled wash water, so there needs to be a testing and changing policy in place and implemented.

- Worker hygiene – Since the harvesters are touching every cherry cluster they harvest during the harvesting process and the packers are sorting through the cherries during the hand sort, there is a lot of actual handling taking place. Whether they are using their bare hands or gloves, there needs to be a hygiene policy in place to ensure that hand washing occurs every time before they return to work, and if they are using gloves, that they are clean and/or switched out regularly.

There are many more items to be taken into consideration, but this is just a brief list to get you thinking about it!

Postharvest Considerations

The most important factor for maintaining the longest shelf-life possible for cherries is to get the fruit cooled down as quickly as possible after harvest. That includes getting the harvested fruit to the packer, through the packing line and into the cooler.

Frequently Asked Questions

When is cherry season?

Cherry season in the United States starts around the end of April / beginning of May in California, and then moves up to the Oregon and Washington crop, which stops harvesting around the end of August.

The Chilean cherry season runs from November to February. Those are the cherries you are most likely to find in supermarkets in the United States during the winter!

Where are cherries grown?

In the United States, sweet cherries (the ones you buy and eat fresh) are grown mainly in California, Oregon and Washington. While, sweet cherries (those traditionally found in confectionary items) are mainly grown in Michigan.

Cherries that are imported from other countries during the winter in the United States are mainly from Chile, with some from Argentina.

Are any harvesting tools used to harvest cherries?

No, they are harvested by hand. During the harvesting process, they remain in large clusters (how they grow) until they reach the packing line where the cherries are individualized.

What is the common sanitizer used in the wash water to wash cherries?

Two of the most common sanitizers used in the wash water at cherry packing houses are Peroxyacetic acid (also known as Peracetic acid and PAA) and chlorine (sodium hypochlorite bleach).

What is the point of using a hydrocooler during cherry packing?

A hydrocooler essentially gives the cherries a bath with cold water to alter the internal temperature of the fruit during the packing process. The purpose of this is to cool down all of the fruit to the same approximate temperature during the packing process, so that they will all enter the cooler at the same temperature range.

Featured Grower Information

I would like to thank The Flavor Tree Fruit Company for the tour and for letting me share the gathered content. The Flavor Tree Fruit Company is based out of Hanford, California and grows and/or markets the following products: cherries (including the early-season Sequoia variety that is featured in this post), the Verry Cherry Plum, pomegranates and California Gold Golden Kiwifruit.

If you enjoyed this post, here are a few more you might enjoy:

It’s amazing all of the steps they take to process fruit. What a great thing for people to be able to see! I’m sure most people don’t realize all of the steps taken to get fruit from the farm to the store. It would be great to be able to see some other types of fruit processing 🙂 Keep up the interesting blogs!

Hi Fruitaholic, thank you for the feedback! Stay tuned for some more behind the scenes posts!