Sun dried tomato processing is really a sight to see! We have already seen how fruit is dried in the field with figs, but the tray drying process that takes place with sun dried tomatoes is a whole different type of operation. We are also lucky to be able see how sun dried tomatoes are made on a really large scale, as this footage was taken at The Morning Star Company, which is the world’s leading tomato ingredient supplier.

Table of Contents

Tomato Harvest

Tomatoes that are destined for the fresh market are hand harvested prior to ripening. However, when tomatoes are harvested for further processing (e.g., to be used in tomato sauce, tomato paste, diced tomatoes, dried tomatoes, tomato powder, spice mixes, etc.), they are able to ripen on the vine and are collected from the field using a harvesting machine. This process also results in a lower harvesting cost, as there are less workers needed during the harvesting process.

Tomato Harvesting Machine

Once the tomatoes are collected by the harvesting machine, the tomatoes go through three steps:

- The machine kicks out the soil from the ground and the initial step removes the field debris that was collected with the tomatoes, using a suction fan that blows the debris out the back of the harvesting machine.

- A color sorter is used to remove any green tomatoes.

- Workers hand sort the tomatoes to catch any discolored tomatoes or field debris that made it through the two previous machine steps. The tomatoes are then transported over into the adjacent trailer on a conveyor belt.

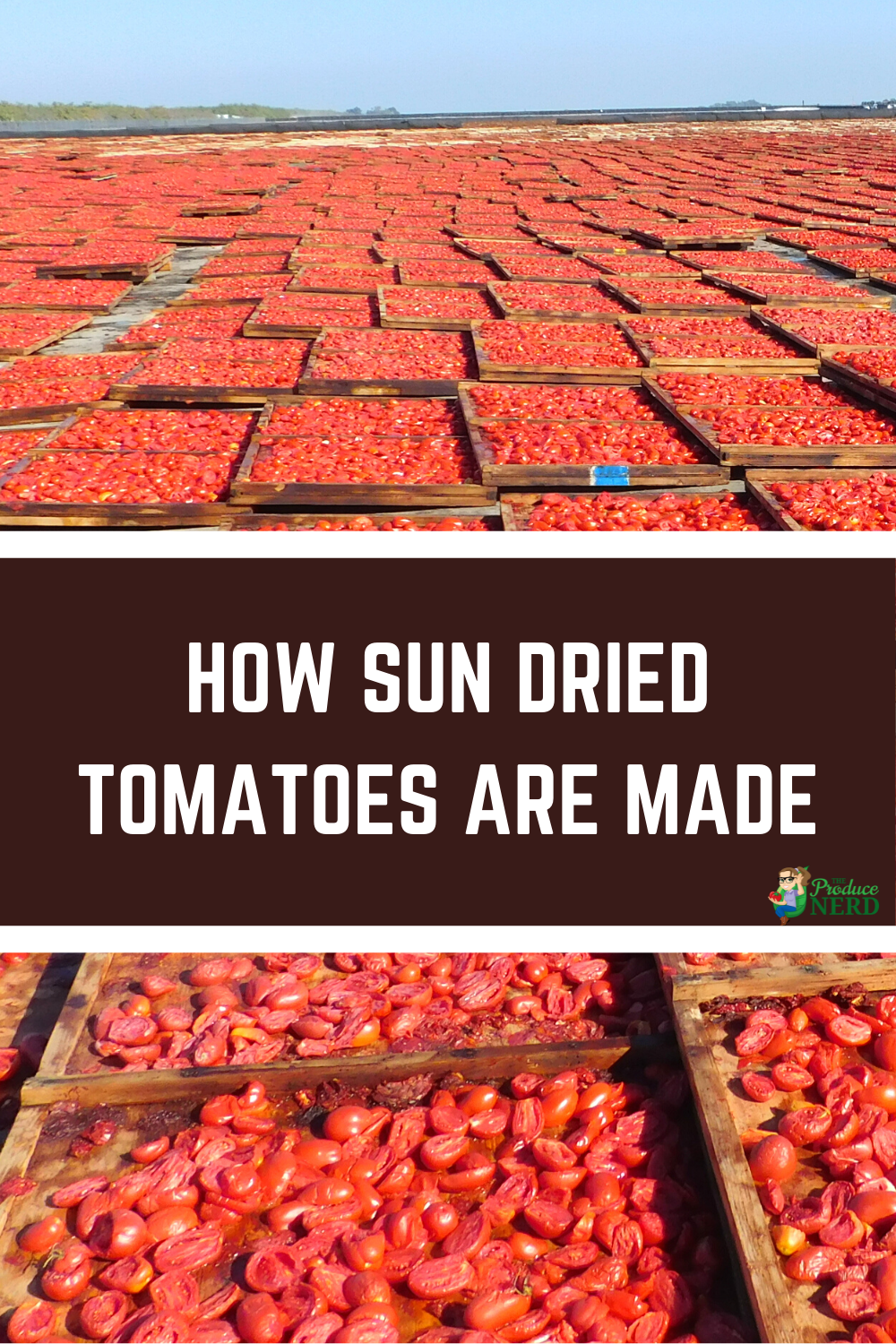

Sun Drying Tomatoes

Although there is a smaller budget needed to harvest processing tomatoes, there is a large amount of labor required during the drying process, as there are multiple steps and a lot of the work needs to be done manually. Check out the video below for the full step-by-step view of sun dried tomato processing.

- Arrival – The tomatoes arrive at the drying facility, where they are unloaded out the side of the trailer with water.

- Rinse, Size, Slice & Prepare Trays – The tomatoes are transported on a conveyor line to be rinsed with sanitized water, sorted by small, medium and large sizes, sliced in half and placed on drying trays.

- Store – The stacks of trays full of tomatoes are placed overnight in storage rooms where they are gassed with sulfur dioxide, which acts as a preservative, or in a dehydrating room. This is determined by the customer’s request.

- Drying Yard – The trays of tomatoes are laid out to dry in the sun for 9 – 14 days, and are picked up once the tomatoes have reached the desired moisture content. All of the work done in the drying yard is where the manual labor is required, as all of the trays need to be manually placed and picked up in the drying yard.

- Pack – The dried tomatoes are scraped off the trays, sorted mechanically and by hand, and are packaged into bulk bins.

- Store – Since tomatoes are only harvested for a few months out of the year, they are processed as they come in from the field and the dried tomatoes are then stored until an order arrives.

Packing Dried Tomatoes

When an order is received, the processed bins are taken out of storage and are packaged to meet customer specifications. There is even the option of increasing the moisture content of the dried tomatoes by adding water.

As you can see, there are a lot of additional steps when it comes to processing operations because at this stage, you are altering the product, not just harvesting, washing or packing it.

Frequently Asked Questions

How are the tomatoes used for sun dried tomatoes harvested?

They are harvested using a tomato harvesting machine that essentially goes through and mows the tomato vines.

Are sun dried tomatoes able to fully ripen on the vine before being harvested?

Yes. Since the tomatoes used for sun dried tomatoes do not need to be perfectly intact for the produce display at the grocery store, they can be vine-ripened. That also allows for them to be machine harvested.

How long do tomatoes need to dry in the sun for?

Tomatoes are dried on trays in the sun for 9 – 14 days. The exact timeframe is determined based on the moisture content of the tomatoes as they are drying.

Are there any protective barriers covering the trays from birds or any sort of insects?

No. These trays are fully exposed to the elements.

What happens to the trays of tomatoes that are drying in the sun if it rains?

If it rains (or even if rain is expected) during the sun drying process, the trays are re-stacked and then once the rain passes, the trays are then placed out on the ground to dry again.

Why is Sulfur Dioxide used with sun dried tomatoes?

Sulfur Dioxide is used as a preservative with sun dried tomatoes, and is also very commonly used with a lot of other dried fruits.

Featured Grower Information

I would like to send a big thank you to The Morning Star Company (sun drying operation) and Perez Farms (harvesting operation) for allowing me to come for a tour and to share the gathered content. The Morning Star Company focuses on processed tomatoes, including diced tomatoes, tomato paste, sun dried tomatoes and fire roasted tomatoes.

If you enjoyed this post, here are some other posts that may be of interest: